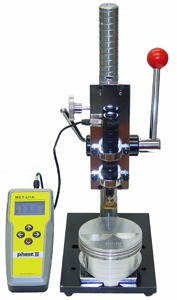

Ultrasonic Non-Destructive Portable Hardness Tester

Model No. PHT-METU1A

The PHASE II ultrasonic/dynamic portable hardness testers are capable of measuring the surface hardness of a broad variety of metals on flat, round, thin or large surfaces. Unlike the standard Dynamic hardness testers, these "state-of-the-art"portable hardness testers incorporate "Ultrasonic UCI"technology, which enables the hardness testing of very thin and small workpieces, which otherwise could not be tested accurately using a portable device. Non-destructive in it's function, these portable hardness testers allow for the testing of highly sensitive or finished parts that previously could not be tested in an operational setting. The non-destructive (ndt) feature of these portable hardness testers allow the operator to accurately test parts without causing physical or structural damage that would normally lead to disposal or refinish of operators part.The Phase II MET series of portable hardness testers offer a model that includes a dynamic probe for easy, quick hardness testing of parts with a mass greater than 5kg

UCI Hardness Testing Method:

MET-U1A and MET-UD

A hardness testing method based on the measurement of the frequency shift of a resonating rod caused by the essentially elastic nature of the finite area of contact between the indenter and the test piece during the penetration. Described as a hardness testing practice using a calibrated instrument by pressing a resonating rod with a Vickers style Diamond indentor with a fixed force against the surface of the part to be tested.

LEEB Hardness Testing Method:

MET-UDA only

This is a dynamic hardness test method using a calibrated instrument that impacts a spherically shaped carbide ball with a fixed velocity (generated by a spring force) onto a surface of the material under test. The ratio of the rebound velocity to the impact velocity of the impact body is a measure of the hardness of the material under test.

| Functions: |

|

| Standard Accessories: |

|

| Optional Accessories: |

|

Technical Data for UCI Probe and Dynamic Indentor:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

* Shown with optional stand * Shown with optional stand |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||